Add:No.52,Linyu Road,Nanbin Sub-district,Ruian City(Beside Linyang School)

Tel:0577-65590157

Fax:0577-65598286

Contact:Mr Jin

mobile phone:13806538205

QQ:494651928

Email:494651928@qq.com

site Url:www.65590157.com

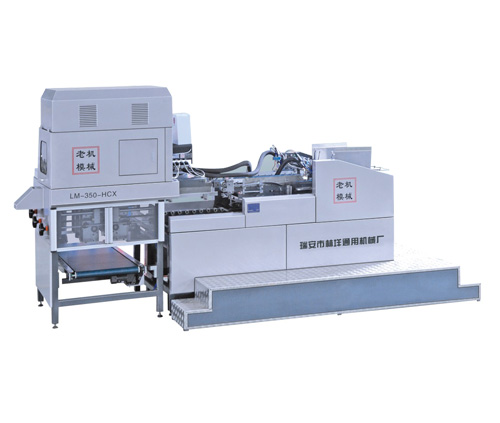

| LM-350-HCX Full automatic cover and bottom box making machine (shoe box) |

|

LM-350-HCX Full automatic cover and paste machine (shoe box machine)

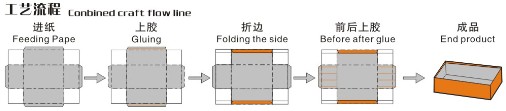

LM-350-HCX型 全自动天地盖糊合机(鞋盒机)是我厂研制的自动化设备,该机采用PLC编程控制器、触摸屏人机界面、光电跟踪系统、伺服控制系统及自动涂胶系统,实现纸板的输送、涂胶、折边、成型及整理纸盒的各部分工艺,全过程自动化,生产效率与传统的手工提高数十倍以上,是各纸盒生产商更新换代的理想设备。 The LM-350-HCX fully automatic heaven and earth lid pasting machine (shoe box machine) is an automated equipment developed by our factory. The machine adopts a PLC programming controller, touch screen human-machine interface, photoelectric tracking system, servo control system, and automatic gluing system to achieve various processes of cardboard transportation, gluing, folding, forming, and organizing paper boxes. The entire process is automated, and the production efficiency is improved by tens of times compared to traditional manual methods, It is an ideal equipment for various paper box manufacturers to update and upgrade.

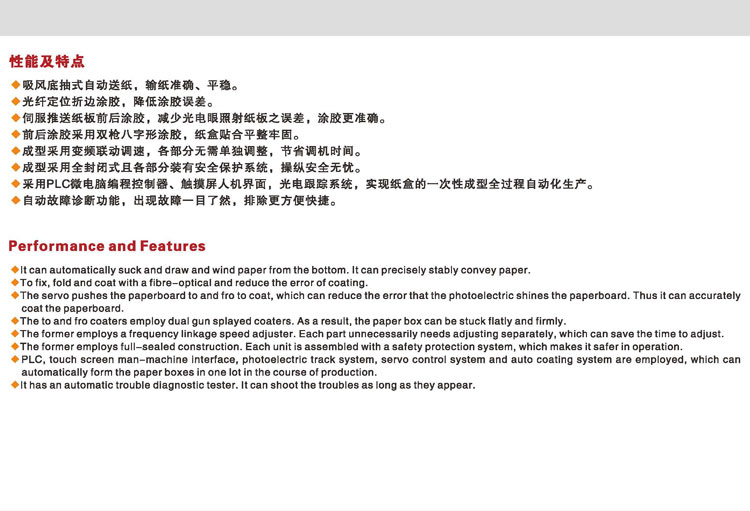

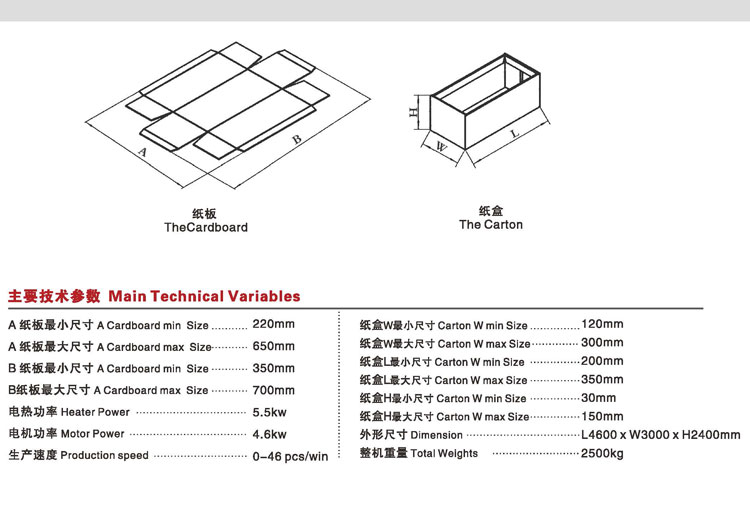

技术参数: A纸板最小尺寸:220mm A纸板最大尺寸:650mm B纸板最小尺寸:350mm B纸板最大尺寸:700mm 电热功率:5.5kw 电机功率:4.6kw 生产速度:40PCS/win 纸盒W最小尺寸:120mm 纸盒W最大尺寸:300mm 纸盒L最小尺寸:200mm 纸盒L最大尺寸:350mm 纸盒H最小尺寸:30mm 纸盒H最大尺寸:150mm 外形尺寸:L4600×W3000×H2400mm 整机重量:2500kg 特点: 1、吸风底抽式自动卷纸,输纸准确、平稳。 2、光纤定位折边涂胶,除低涂胶误差。 3、伺服推送纸板前后涂胶,减少光电眼照射纸板之误差,涂胶更准确。 4、前后涂胶采用双枪八字形涂胶,纸盒贴合平整牢固。 5、成型采用变频联动调速,各部分无需单独调整,节省调机时间。 6、成型采用全封闭式且各部分装有安全保护系统,操纵安全无忧。 7、采用PLC微电脑编程控制器、触摸屏人机界面、光电跟踪系统、实现纸盒的一次性成型全过程自动化生产。 8、自动故障诊断功能,出现故障一目了然,排除更方便快捷。 Features: 1. The suction bottom suction automatic paper roll ensures accurate and stable paper feeding. 2. Fiber optic positioning fold edge coating, eliminating low coating errors. 3. Servo push of cardboard before and after gluing reduces the error of photoelectric eye irradiation on the cardboard, resulting in more accurate gluing. 4. The front and back glue are applied in a double gun eight shaped pattern, and the paper box is firmly and smoothly bonded. 5. The molding adopts variable frequency linkage speed regulation, and each part does not need to be adjusted separately, saving adjustment time. 6. The molding adopts a fully enclosed design and each part is equipped with a safety protection system, ensuring worry free operation. 7. Adopting PLC microcomputer programming controller, touch screen human-machine interface, photoelectric tracking system, to achieve the automation of the entire process of one-time molding of paper boxes. 8. The automatic fault diagnosis function makes it clear at a glance when faults occur, making troubleshooting more convenient and efficient. |

Mr Jin

Mr Jin